11 Jan Why the Human Element is Critical to Enterprise IoT

As with most technology adoption, the enterprise lags behind consumers. While consumers have long integrated smartphone and mobile app usage into their lives, most enterprises are still in the process of fully deploying modern mobile applications that connect to their enterprise systems. Today, consumers are already adopting the Internet of Things (IoT) all throughout their households (“Alexa, what’s tomorrow’s weather forecast?” “OK, Google, turn off the TV and the lights in the den.”), while the enterprise is just starting to think about how IoT technologies can be integrated. As we move into 2017, the enterprise will continue its digital transformation by adopting new cloud-based platforms and equipping their field service teams with mobile access to these systems.

Providing field service technicians with mobile devices that are loaded with your enterprise apps gives them access to the right information at the right time in any location (even potentially treacherous ones). This is a huge leap forward in productivity and improves safety for all field workers. In the next 10 years, IoT will be mainstream in the enterprise and, when combined with mobile-enabled field technicians, it will supercharge field operations by providing timely and actionable information-driven insights about equipment and the enterprise infrastructure.

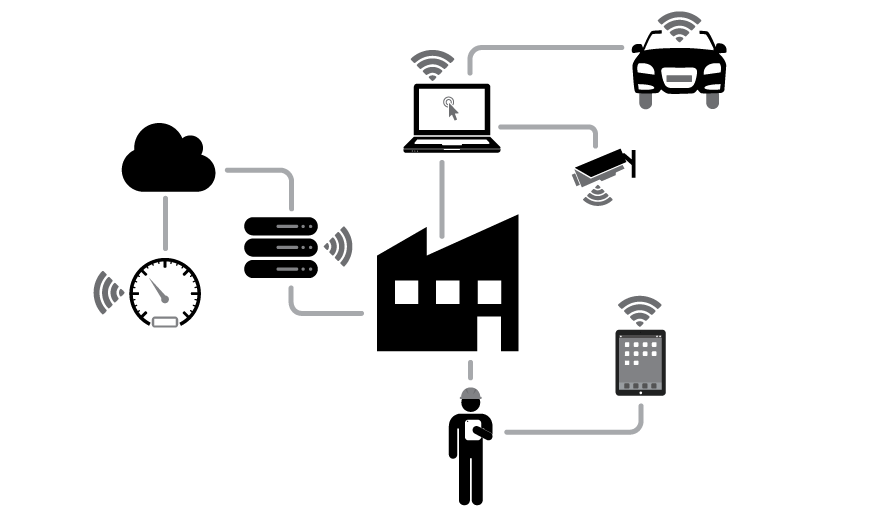

Enterprise IoT starts with asset sensors, bringing new opportunities to asset managers for insight into efficiency, utilization, wear and tear, and maintenance. Asset managers can gain unprecedented levels of detail and control within asset tracking systems.

But EIoT is about more than just collecting richer data from sensors. Its true value for the enterprise resides in connecting people to these otherwise disconnected “things.” Fully realized EIoT provides field techs deep insights from data analysis, allowing individuals and teams to make better and more informed business decisions.

An example of this comes from the oil and gas industry. The enterprise has more than a thousand field technicians that perform a variety of surveys, assessments, and work orders. They have taken hundreds of paper forms and built electronic versions within their ServiceNow platform. They utilize Mobile Reach to push the web forms to their field techs who are, in some cases, working on an oil rig in the middle of the ocean and therefore have no Internet connectivity. These web forms include job safety evaluations that require the technician to take timed pressure or gas readings on a very strict schedule. Currently, these are performed manually by the technician; however, the next step would be to leverage IoT devices so these pressure or gas readings can be taken while they performing other tasks. They also aren’t subject to human error or recording errors because they are automatically fed into the mobile application. The technician can then take appropriate actions if readings are unsafe or require parts to repair, and appropriate parts can be ordered immediately while on site. When field technicians are equipped with mobile devices that can connect to EIoT devices and sensors, the field service organization derives transformative value through enabling more efficient business processes, greater productivity, safety and reliability.

An example of this comes from the oil and gas industry. The enterprise has more than a thousand field technicians that perform a variety of surveys, assessments, and work orders. They have taken hundreds of paper forms and built electronic versions within their ServiceNow platform. They utilize Mobile Reach to push the web forms to their field techs who are, in some cases, working on an oil rig in the middle of the ocean and therefore have no Internet connectivity. These web forms include job safety evaluations that require the technician to take timed pressure or gas readings on a very strict schedule. Currently, these are performed manually by the technician; however, the next step would be to leverage IoT devices so these pressure or gas readings can be taken while they performing other tasks. They also aren’t subject to human error or recording errors because they are automatically fed into the mobile application. The technician can then take appropriate actions if readings are unsafe or require parts to repair, and appropriate parts can be ordered immediately while on site. When field technicians are equipped with mobile devices that can connect to EIoT devices and sensors, the field service organization derives transformative value through enabling more efficient business processes, greater productivity, safety and reliability.

Enterprises must make these digital transformations and adopt mobile platforms that are flexible enough to adapt to the rapidly changing environment in order to attain new levels of customer service, business process efficiency, operational awareness, and ultimately greater profitability.